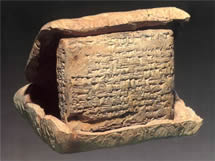

As history goes, the envelope is a comparative newcomer, but its predecessors go back as far as recorded history.Old envelope Perhaps the first of these "envelopes" was the clay wrapper used by the Babylonians in 2000 B.C. to protect documents such as bookkeeping accounts, deeds, mortgages, and quite possibly letters as well. The clay in its plastic state was folded over the original message, crimped together, then baked. It was a foolproof system, for the outside wrapper had to be completely destroyed in order to gain access to the tablet hidden under it. This was hardly a convenient kind of package to transport, and such messages as had to be carried came to be written on lighter materials: tile, skin, leaves, papyrus.

Little is known about how these later documents were protected from prying eyes, but it is doubtful that anything like our present day envelopes were made of parchment or papyrus. Lengthy scrolls were sometimes rolled on thin wood, then wrapped in a covering of the same material on which the massage was inscribed.

Paper came into use in the 10th Century, and by the 15th Century posts were considered a necessary part of each well-run kingdom. From the very first the Crown, or central government, not only organized the posts but operated them as a monopoly of the state. Henry VIII of England appointed Brian Tuke as his Master of the Posts in 1510, and from that time on such terms as royal posts and King's Highway are encountered in literature. The modern postal system was at least on its way!

In the 16th Century official letters, and letters sent by important people, were mailed, as Grand-Cartiret puts it, "under cover or envelope." The message was enclosed in a paper that was folded and sealed.

Each sender had to take care of his own "enveloping," and would cut the paper as he saw fit.

The few specimens that have come down through the years are obviously individually made, with no uniform cut or pattern.

No one will ever know who it was that first conceived the idea of cutting paper for envelopes from a standard pattern. No doubt it was a stationer who sold paper, and realized that there was a need to be filled. The stationer who first folded and fabricated envelopes by hand has no monument to mark his achievement, unless the hundreds of envelope-producing plants all over the world be considered as such.

On July 31, 1635, King Charles I issued a proclamation from his court at Bagshot establishing the first State postal service for the conveyance of private letters in England and Scotland, and appointing one Thomas Witherings, Esquire, to organize and manage the new system.

A strikingly modern idea was tried out in France in 1635. M.de Valayer obtained the permission of King Louis XIV to establish a postal system in Paris. He set up boxes at street corners, and announced by handbill that he was prepared to deliver any letters placed in them provided they were enclosed in the envelopes that he place on sale at certain stores.

These envelopes were in the nature of wrappers, but as they contained a printed receipt for postage paid, they were, at least in idea, amazingly like the government stamped envelopes that came along nearly 200 years later.

De Valayer's scheme failed, and it is generally thought that it was sabotaged by certain interests who feared its success. At any rate the whole idea was ridiculed, and any chance for success that it might have had was ruined by the dumping of refuse and live mice into the receiving boxes. Naturally, the public would not use a service so undependable, and de Valayer had to give up.

In 1845, Edwin Hill and Warren De La Rue were granted a British patent for the first envelope-making machine.

The "envelopes" produced by the Hill/De La Rue machine were not as we know them today. They were flat diamond, lozenge {or rhombus)-shaped sheets or "blanks" which had been precut to shape before being fed to the machine for creasing and made ready for folding to form a rectangular enclosure. The edges of the overlapping flaps treated with a paste or adhesive and the method of securing the envelope or wrapper was a user choice. The symmetrical flap arrangement meant that it could be held together with a single wax seal at the apex of the topmost flap. (That the flaps of an envelope can be held together by applying a seal at a single point is a classic design feature of an envelope). Nearly 50 years passed before a commercially successful machine for producing pre-gummed envelopes effectively as we know them today appeared.

The origin of the use of the diamond shape for envelopes is debated. However as an alternative to simply wrapping a sheet of paper around a folded letter or an invitation and sealing the edges, it is a tidy and ostensibly paper-efficient way of producing a rectangular-faced envelope. The claim to be paper-efficient fails because the paper manufacturers normally making paper available in rectangular sheets, because cutting a diamond shape from a rectangular shape inevitably generates waste.

Their use first became widespread in the UK when the British government took monoply control of postal services and tasked Rowland Hill with its introduction. The new service was launched in May 1840 with a postage-paid machine-printed pictorial version of the wrapper and the much-celebrated first adhesive postage stamp: the Penny Black.The wrappers were printed and sold as a sheet of 12, with cutting the purchaser's task.The illustration on the wrapper was ridiculed and they were withdrawn and replaced by a simpler version. Nevertheless the public apparently saw the convenience of the wrapper, and it must have been obvious that with the stamp available totally plain versions of the wrapper could be produced and postage prepaid by purchasing a stamp and affixing it to the folded and secured wrapper.

At the end of the 20th century a top of the range envelope-making machine cost in the region of $1 million and could produce 1200 pre-gummed envelopes per minute in boxes of 1000 ready for distribution. With manufacturing costs as high as this very few envelope-making machinery manufacturers appeared in the 19th and 20th centuries, and at the beginning of the 21st century the number satisfying the world demand remained low, with a single enterprise, Winkler and Dunnebier, producing two-thirds of the machines producing the 450 billion envelopes referred to above.

Consequently too the high cost of buying these high capital investment machines has to be factored into the operating costs of any enterprise which engages in producing printed envelopes, and so their line of business is the production of very large runs of the order of 50,000 and upwards. Depending on the size of the run this can entail the use of an entire web or reel. The result of this is that over the last 150 years or so the most common way of producing printed envelopes commercially has been to overprint on machine-made envelopes. Needless to say, only the largest of companies have a need for 50,000 or more envelopes at any one time.

The drawback is that although printing on the face of an envelope is reasonably straight- forward, an envelope is not a flat sheet of paper and so if printing is required on one or more flaps this incurs higher cost as specialist printing skill is required.

EnvelopeFor small businesses with a need for relatively low volumes of printed envelopes, even if a case is made for a batch customized with no more than the company logo on the face, there is seldom justification for the added expense of printing on the flap side too. However the volume-related barrier to the use of customized envelopes by small businesses was subsequently lowered in the late-20th century with the advent of the digital printing revolution which saw the introduction of PC printers. Although designed primarily to process flat rectangular sheets these could be adjusted to also overprint on the face of rectangular machine-made envelopes in spite of the extra thickness - given suitable software